Call us 8:00am - 8:00pm

079-2273 3345 / 6353949804

Monday to Friday

8:00am - 8:00pm

Service Details

- Arcellor Controls | Welcome to Arcellor Controls (India)

- Service Details

Services

Tongue and Groove Flange Manufacturers in India

ASME B16.5 Tongue and Groove Flanges, Tongue and Groove Flange Dimensions

Tongue and Groove Weld Neck Flange, Tongue and Groove Blind Flange, Tongue and Groove Pipe Flange

Tongue and Groove Flange Gasket, ANSI Tongue and Groove Flange Dimensions, Small Tongue and Groove Flange Dimensions, DIN Tongue and Groove Flange

Tongue and Groove Flange Manufacturer

Groove and Tongue Flange

Arcellor Controls is distinguished Tongue and Groove Flanges Manufacturers in India,Tongue and Groove faces of this flanges must be matched. One Tongue flange face has a raised ring machined onto the flange face while the mating grooving flange has a matching depression machined into it’s face.Tongue-and-groove facings are standardized in both large tongue and groove flange and small tongue and groove flange, different from male-and-female in that the inside diameters of the groove and tongue do not extend into the flange base, thus retaining the gasket on its inner and outer diameter. Our offered Tongue and Groove flange applications are commonly on pump covers and Valve Bonnets.

Tongue and groove joints also have an advantage in that they are self-aligning and act as a reservoir for the adhesive. The scarf joint keeps the axis of loading in line with the joint and does not require a major machining operation.General flange faces such as Tongue and Groove flange shall never be bolted together because of there contact surfaces do not match and there is no tongue and groove flange gasket that has one type on one side and another type on the other side.

Tongue and Groove Flange Face, Gasket for Tongue and Groove Flange, tongue-and-groove (t&g) flange, tongue and groove flange joint

large tongue and groove flange dimensions, tongue and groove type flange, tongue and groove flange applications

ANSI/ASME B16.5 Groove and Tongue Flange Standard Specification

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

ASME B16.5 Tongue and Groove Flange Material Specification

Stainless Steel Tongue and Groove Flange:

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Groove and Tongue Flange :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Tongue and Groove Flange:

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Groove and Tongue Flange: ASTM A350, LF2, LF3

Alloy Steel Groove and Tongue Flange:

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Tongue and Groove Flange : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Groove and Tongue Flange:

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

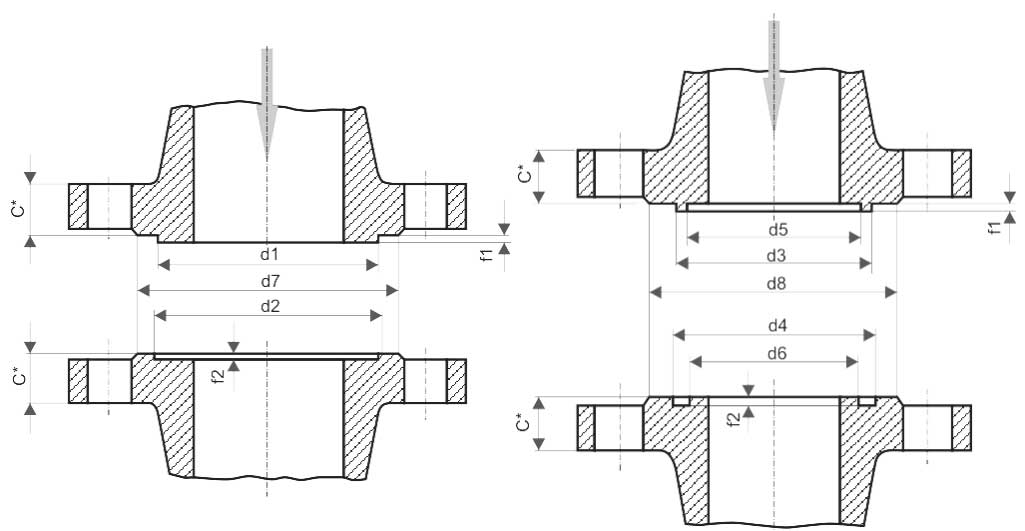

ANSI B16.5 TONGUE AND GROOVE FLANGE DIMENSIONS

| DN | d1 | d2 | d3 | d4 | d5 | d6 | d7 | d8 | f1 | f2 |

| ½” | 1,38 (35,1) |

1,44 (36,6) |

1,38 (35,1) |

1,44 (36,6) |

1,00 (25,4) |

0,94 (23,9) |

1,81 (46,0) |

1,75 (44,5) |

0,25 (6,4) |

0,19 (4,8) |

| ¾” | 1,69 (42,9) |

1,75 (44,5) |

1,69 (42,9) |

1,75 (44,5) |

1,31 (33,3) |

1,25 (31,8) |

2,12 (53,8) |

2,06 (52,3) |

0,25 (6,4) |

0,19 (4,8) |

| 1″ | 2,00 (50,8) |

2,06 (52,3) |

1,88 (47,7) |

1,94 (49,3) |

1,50 (38,1) |

1,44 (36,6) |

2,44 (62,0) |

2,25 (57,2) |

0,25 (6,4) |

0,19 (4,8) |

| 1¼” | 2,50 (63,5) |

2,56 (65,0) |

2,25 (57,2) |

2,31 (58,7) |

1,88 (47,8) |

1,81 (46,0) |

2,94 (74,7) |

2,62 (66,6) |

0,25 (6,4) |

0,19 (4,8) |

| 1½” | 2,88 (73,2) |

2,94 (74,7) |

2,50 (63,5) |

2,56 (65,0) |

2,12 (53,8) |

2,06 (52,3) |

3,31 (84,1) |

2,88 (73,2) |

0,25 (6,4) |

0,19 (4,8) |

| 2″ | 3,62 (92,0) |

3,69 (93,7) |

3,25 (82,6) |

3,31 (84,1) |

2,88 (73,0) |

2,81 (71,4) |

4,06 (103,1) |

3,62 (92,0) |

0,25 (6,4) |

0,19 (4,8) |

| 2½” | 4,12 (104,6) |

4,19 (106,4) |

3,75 (95,2) |

3,81 (96,8) |

3,38 (85,8) |

3,31 (84,1) |

4,56 (115,8) |

4,12 (104,6) |

0,25 (6,4) |

0,19 (4,8) |

| 3″ | 5,00 (127,0) |

5,06 (128,5) |

4,62 (117,5) |

4,69 (119,1) |

4,25 (108,0) |

4,19 (106,4) |

5,44 (138,2) |

5,00 (127,0) |

0,25 (6,4) |

0,19 (4,8) |

| 4″ | 6,19 (157,2) |

6,25 (158,8) |

5,69 (144,5) |

5,75 (146,1) |

5,19 (131,8) |

5,12 (130,0) |

6,62 (168,1) |

6,19 (157,2) |

0,25 (6,4) |

0,19 (4,8) |

| 5″ | 7,31 (185,7) |

7,38 (187,5) |

6,81 (173,0) |

6,88 (174,8) |

6,31 (160,3) |

6,25 (158,8) |

7,75 (196,9) |

7,31 (185,7) |

0,25 (6,4) |

0,19 (4,8) |

| 6″ | 8,50 (215,9) |

8,56 (217,5) |

8,00 (203,2) |

8,06 (204,7) |

7,50 (190,5) |

7,44 (189,0) |

8,94 (227,0) |

8,50 (215,9) |

0,25 (6,4) |

0,19 (4,8) |

| 8″ | 10,62 (269,8) |

10,69 (271,5) |

10,00 (254,0) |

10,06 (255,5) |

9,38 (238,3) |

9,31 (236,5) |

11,06 (281,0) |

10,62 (269,8) |

0,25 (6,4) |

0,19 (4,8) |

| 10″ | 12,75 (323,5) |

12,81 (325,4) |

12,00 (304,8) |

12,06 (306,3) |

11,25 (285,8) |

11,19 (284,2) |

13,19 (335,0) |

12,75 (323,5) |

0,25 (6,4) |

0,19 (4,8) |

| 12″ | 15,00 (381,0) |

15,06 (382,5) |

14,25 (362,0) |

14,31 (363,5) |

13,50 (342,9) |

13,44 (341,4) |

15,44 (392,2) |

15,00 (381,0) |

0,25 (6,4) |

0,19 (4,8) |

| 14″ | 16,25 (412,8) |

16,31 (414,3) |

15,50 (393,7) |

15,56 (395,2) |

14,75 (374,7) |

14,69 (373,1) |

16,69 (423,9) |

16,25 (412,8) |

0,25 (6,4) |

0,19 (4,8) |

| 16″ | 18,50 (469,9) |

18,56 (471,5) |

17,62 (447,6) |

17,69 (449,3) |

16,75 (425,5) |

16,69 (423,9) |

18,94 (481,0) |

18,50 (469,9) |

0,25 (6,4) |

0,19 (4,8) |

| 18″ | 21,00 (533,4) |

21,06 (535,0) |

20,12 (511,0) |

20,19 (512,8) |

19,25 (489,0) |

19,19 (487,4) |

21,44 (544,6) |

21,00 (533,4) |

0,25 (6,4) |

0,19 (4,8) |

| 20″ | 23,00 (584,2) |

23,06 (585,8) |

22,00 (558,8) |

22,06 (560,3) |

21,00 (533,4) |

20,94 (531,9) |

23,44 (595,4) |

23,00 (584,2) |

0,25 (6,4) |

0,19 (4,8) |

| 24″ | 27,25 (692,2) |

27,31 (693,7) |

26,25 (666,8) |

26,31 (668,3) |

25,25 (641,4) |

25,19 (639,8) |

27,69 (703,3) |

27,25 (692,2) |

0,25 (6,4) |

0,19 (4,8) |

ANSI B16.5 Class 150# Large Tongue & Groove Flanges Dimensions

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<300 |

4800 |

7 |

10000 |

14 |

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.50 |

60 |

7560 |

33791 |

<300 |

4800 |

9 |

10000 |

18 |

1 |

1.50 |

2.00 |

1.37 |

4 |

0.50 |

60 |

7560 |

22013 |

<300 |

4800 |

13 |

10000 |

27 |

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.50 |

60 |

7560 |

14186 |

<300 |

4800 |

20 |

10000 |

42 |

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.50 |

60 |

7560 |

10137 |

<300 |

4800 |

28 |

10000 |

59 |

2 |

2.88 |

3.62 |

3.78 |

4 |

0.63 |

120 |

12120 |

12839 |

<300 |

4800 |

45 |

10000 |

93 |

2.5 |

3.38 |

4.12 |

4.36 |

4 |

0.63 |

120 |

12120 |

11128 |

<300 |

4800 |

52 |

10000 |

108 |

3 |

4.25 |

5.00 |

5.45 |

4 |

0.63 |

120 |

12120 |

8902 |

<300 |

4800 |

65 |

8902 |

120 |

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.63 |

120 |

12120 |

16067 |

<300 |

4800 |

36 |

10000 |

75 |

4 |

5.19 |

6.19 |

8.93 |

8 |

0.63 |

120 |

12120 |

10854 |

<300 |

4800 |

53 |

10854 |

120 |

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<300 |

4800 |

71 |

13558 |

200 |

6 |

7.50 |

8.50 |

12.56 |

8 |

0.75 |

200 |

18120 |

11541 |

<300 |

4800 |

83 |

11541 |

200 |

8 |

9.38 |

10.62 |

19.47 |

8 |

0.75 |

200 |

18120 |

7446 |

<300 |

4800 |

129 |

7446 |

200 |

10 |

11.25 |

12.75 |

28.26 |

12 |

0.88 |

320 |

25140 |

10675 |

<300 |

4800 |

144 |

10675 |

320 |

12 |

13.50 |

15.00 |

33.56 |

12 |

0.88 |

320 |

25140 |

8990 |

<300 |

4800 |

171 |

8990 |

320 |

14 |

14.75 |

16.25 |

36.50 |

12 |

1.00 |

490 |

33060 |

10868 |

<300 |

4800 |

216 |

10868 |

490 |

16 |

16.75 |

18.50 |

48.42 |

16 |

1.00 |

490 |

33060 |

10923 |

<300 |

4800 |

215 |

10923 |

490 |

18 |

19.25 |

21.00 |

55.29 |

16 |

1.13 |

710 |

43680 |

12639 |

<300 |

4800 |

270 |

12639 |

710 |

20 |

21.00 |

23.00 |

69.08 |

20 |

1.13 |

710 |

43680 |

12646 |

<300 |

4800 |

269 |

12646 |

710 |

24 |

25.25 |

27.25 |

82.43 |

20 |

1.25 |

1000 |

55740 |

13525 |

<300 |

4800 |

355 |

13525 |

1000 |

ANSI B16.5 Class 300# Large Tongue & Groove Flanges Dimensions

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<800 |

6200 |

12 |

10000 |

14 |

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.63 |

120 |

12120 |

54174 |

<800 |

6200 |

21 |

10000 |

22 |

1 |

1.50 |

2.00 |

1.37 |

4 |

0.63 |

120 |

12120 |

35290 |

<800 |

6400 |

28 |

10000 |

34 |

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.63 |

120 |

12120 |

22742 |

<800 |

6400 |

43 |

10000 |

53 |

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.75 |

200 |

18120 |

24298 |

<800 |

6400 |

64 |

10000 |

82 |

2 |

2.88 |

3.62 |

3.78 |

8 |

0.63 |

120 |

12120 |

25679 |

<800 |

6400 |

46 |

10000 |

47 |

2.5 |

3.38 |

4.12 |

4.36 |

8 |

0.75 |

200 |

18120 |

33273 |

<800 |

6400 |

60 |

10000 |

60 |

3 |

4.25 |

5.00 |

5.45 |

8 |

0.75 |

200 |

18120 |

26618 |

<800 |

6400 |

88 |

10000 |

75 |

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.75 |

200 |

18120 |

24021 |

<800 |

6400 |

99 |

10000 |

83 |

4 |

5.19 |

6.19 |

8.93 |

8 |

0.75 |

200 |

18120 |

16227 |

<800 |

6400 |

125 |

10000 |

123 |

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<800 |

6400 |

156 |

10000 |

148 |

6 |

7.50 |

8.50 |

12.56 |

12 |

0.75 |

200 |

18120 |

17312 |

<800 |

6400 |

131 |

10000 |

116 |

8 |

9.38 |

10.62 |

19.47 |

12 |

0.88 |

320 |

25140 |

15496 |

<800 |

6400 |

205 |

10000 |

207 |

10 |

11.25 |

12.75 |

28.26 |

16 |

1.00 |

490 |

33060 |

18718 |

<800 |

6400 |

219 |

10000 |

262 |

12 |

13.50 |

15.00 |

33.56 |

16 |

1.13 |

710 |

43680 |

20826 |

<800 |

6400 |

319 |

15000 |

511 |

14 |

14.75 |

16.25 |

36.50 |

20 |

1.13 |

710 |

43680 |

23933 |

<800 |

6600 |

287 |

15000 |

445 |

16 |

16.75 |

18.50 |

48.42 |

20 |

1.25 |

1000 |

55740 |

23021 |

<800 |

6600 |

401 |

15000 |

652 |

18 |

19.25 |

21.00 |

55.29 |

24 |

1.25 |

1000 |

55740 |

24194 |

<800 |

6400 |

439 |

15000 |

620 |

20 |

21.00 |

23.00 |

69.08 |

24 |

1.25 |

1000 |

55740 |

19365 |

<800 |

6400 |

484 |

15000 |

775 |

24 |

25.25 |

27.25 |

82.43 |

24 |

1.50 |

1600 |

84300 |

24546 |

<800 |

6400 |

662 |

15000 |

978 |

Types of Tongue and Groove Flanges

| Tongue & Groove Flange | Groove & Tongue Flanges |

| ANSI B16.5 Tongue & Groove Flanges | Tongue & Groove Flange Dimensions |

| Carbon Steel Groove & Tongue Flange | ANSI B16.5 Class 150 Tongue & Groove Flanges |

| Long Tongue & Groove Flanges | SS Groove & Tongue Flange |

| Stainless Steel Tongue & Groove Flanges | ASME B16.47 Series A and B Tongue & Groove Flanges |

| ANSI B16.5 class 150 Tongue & Groove Flange Stockholder | ANSI 150 Tongue & Groove Flange |

| ASME B16.5 Tongue & Groove Flanges | High Quality Tongue & Groove Flanges |

| ANSI Tongue & Groove Flange | Small Tongue & Groove Flange |

| Tongue & Groove Slip On Flange | Tongue & Groove Pipe Flanges |

| Groove & Tongue Flange Dimensions | Small Tongue & Groove Flanges |

| ASME B16.47 Series A and B Tongue & Groove Flanges | Tongue & Groove Weld Neck Flanges |

Tongue and Groove Flange Price List

Groove and Tongue Flange Price: $100.45 / each

Small Tongue and Groove Flange Price: $120.14 / each

Large Tongue and Groove Flange Price: $110.35 / each

Tongue & Groove Flanges Application

ASME B16.5 Groove and Tongue Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Tongue & Groove Flanges through a worldwide network of stock-keeping branches. These Tongue & Groove Flange is use in various industrial applications like :

- Tongue & Groove Flanges uses in Chemical Industry

- Large Tongue & Groove Flanges uses in Plumbing

- ANSI B16.5 Tongue & Groove Flanges uses in Power Plant

- Tongue & Groove Flange uses in Food Processing Industry

- Small Groove & Tongue Flanges uses in Structural Pipe

- Stainless Steel Tongue & Groove Flanges uses in Oil and Gas Pipeline

- Tongue & Groove Flanges uses in Heating

- Tongue & Groove Pipe Flanges uses in Water Supply Systems

- Tongue & Groove Flanges uses in Paper & Pulp Industry

- Groove & Tongue Flange uses in General Purpose Applications

- Steel Tongue & Groove Flanges uses in Fabrication Industry

ASME/ANSI B16.5 Groove and Tongue Flange Supplying to Following Regions & Countries:

| AFRICA Nigeria Algeria Angola Tanzania Libya Egypt Sudan Equatorial Guinea The Republic Of Congo Gabon NORTH AMERICA Usa Canada Mexico Costa Rica Trinidad And Tobago Jamaica Denmark |

MIDDLE EAST ASIA Saudi Arabia Iran Iraq Uae Qatar Bahrain Oman Kuwait Turkey Jordan SOUTH AMERICA Argentina Bolivia Brazil Chile Venezuela Colombia Ecuador Guyana Paraguay Uruguay |

EUROPE Norway Germany France Italy Uk Spain Netherland Belgium Greece Czech Republic Portugal Hungary SOUTH AFRICA |

ASIA India Singapore Malaysia Indonesia Thailand Vietnam South Korea Japan Sri Lanka Maldives Bangladesh Mayanmar Taiwan Cambodia |

Get in Touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.